Drilling and tapping in solid brass.

FIXED- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Printer Friendly Page

- Plusnet Community

- :

- Forum

- :

- Other forums

- :

- Tech Help - Software/Hardware etc

- :

- Re: Drilling and tapping in solid brass.

31-01-2022 3:20 PM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

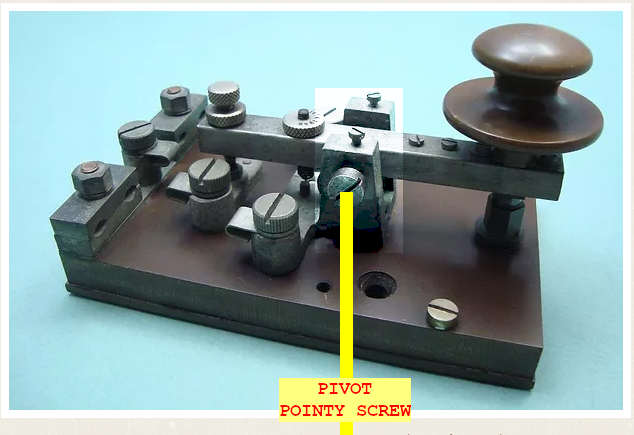

One of my morse keys needs the pivot threads to be re-drilled and tapped to the next size out..

At present, they are 6mm, so the next size up would be 8mm .

Drilling through about 10mm of solid brass. As already drilled and threaded, should not be too difficult to follow through with a bigger drill bit ,

What size drill bit(s) should I use to ensure that the 8mm tap will give a good cut , and not be "slack"

Fixed! Go to the fix.

Re: Drilling and tapping in solid brass.

31-01-2022 3:59 PM - edited 31-01-2022 4:10 PM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

@shutter wrote:

What size drill bit(s) should I use to ensure that the 8mm tap will give a good cut , and not be "slack"

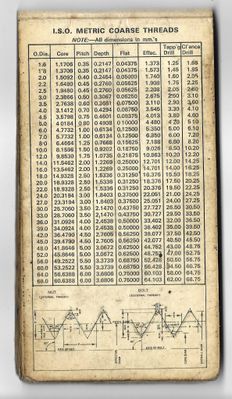

What pitch on the 8mm

1.25 Pitch is a 6.9mm drill

1.00 Pitch is a 7.1mm drill

Are you going to start with a taper tap then a plug or can you drill straight through

I would try on a scrap piece of metal first and use plenty of lubricant and keep it square

If you worried about it being slack use some Loctite or similar

Re: Drilling and tapping in solid brass.

31-01-2022 4:42 PM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

Start with a taper, then use a plug. Use plenty of lubricant with brass and reverse/clear the tap of swarf regularly. It's very easy to clog the tap and end up over cutting the thread.

Moderator and Customer

If this helped - select the Thumb

If it fixed it, help others - select 'This Fixed My Problem'

Re: Drilling and tapping in solid brass.

31-01-2022 4:46 PM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

@Baldrick1 Thanks for the reply... haven`t got a taper, only standard HSS drill bits.. and a set of taps and dies.... I was thinking of starting witha 6.5 thne 7 then 7.5 but not sure if that last would be too much, and not leave enough metal for the thread to be strong.

Re: Drilling and tapping in solid brass.

31-01-2022 5:40 PM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

Not a taper drill, a taper tap. If you start with a small hole you will jam a plug tap.

Moderator and Customer

If this helped - select the Thumb

If it fixed it, help others - select 'This Fixed My Problem'

Re: Drilling and tapping in solid brass.

31-01-2022 6:03 PM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

@Baldrick1 None of my taps are tapered... only what I think you call plugs... ( parallel tapped thread )

I have a 7mm tap, and an 8mm tap, but can only get 8mm pointed grub screws that I need for the job.

Re: Drilling and tapping in solid brass.

31-01-2022 11:51 PM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

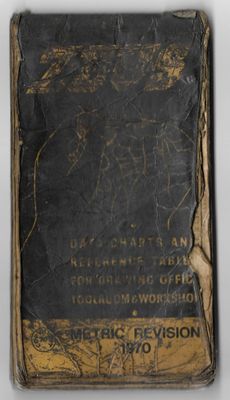

Haven't you got the little yellow book? Probably still have mine from my apprentice days.

Re: Drilling and tapping in solid brass.

01-02-2022 8:39 AM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

@billnotben Huh ? ![]() Only little yellow book I know about is/was yellow pages ! ! ..

Only little yellow book I know about is/was yellow pages ! ! .. ![]()

Re: Drilling and tapping in solid brass.

01-02-2022 10:03 AM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

It was a must have book back then that has been well used.

Re: Drilling and tapping in solid brass.

01-02-2022 10:05 AM - edited 01-02-2022 10:09 AM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

Hmm. Will copy that and then enlarge it, to be able to read it ! ! ! ! ... cheers ![]()

Done ! ... but I still don`t know which size drill bit to use ! ! ! ... ![]()

![]()

![]()

Re: Drilling and tapping in solid brass.

01-02-2022 10:10 AM - edited 01-02-2022 10:15 AM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

Larger.

Which drill? Of course if you're doing it with a hand drill it will depend how steady your hand is. So at the end of the day it will still be a bit of trial and error.

Re: Drilling and tapping in solid brass.

01-02-2022 10:37 AM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

@billnotben I have a choice... a hand cranked drill, or a 12 v portable drill, or a 240v drill I can use in a pillar drill stand... but it is "slightly off" true vertical to the base.

As the hole and thread are already through the brass shoulders, it`s more a case of just widening the diameter of the hole, leaving sufficient to tap the new 8mm thread into it..

Originally it would have been a British Thread,... being made during the 1930`s, but over the years of abuse by hundreds of different "fists" ( wireless telegraphists ) ... the threads have worn somewhat, and are not fit for purpose... i.e. the "pointy screws" that act as the pivot point can "wobble", slightly, which upsets the way the key works, causing errors in transmission.

Re: Drilling and tapping in solid brass.

01-02-2022 11:12 AM - edited 01-02-2022 11:16 AM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

Just to explain the "Pointy pivot screw"

being replaced with this.... https://www.ebay.co.uk/itm/401859514894

M8 A2 Stainless Cone Point Grub Screws Hex Socket Set Screw DIN 914

Note.... Drill Bit Sizes available....6.5mm 7mm 7.5 mm 8mm

Re: Drilling and tapping in solid brass.

01-02-2022 11:35 AM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

@shutter wrote:

... causing errors in transmission.

Random extra dots?

Re: Drilling and tapping in solid brass.

01-02-2022 11:46 AM - edited 01-02-2022 11:56 AM

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Highlight

- Report to Moderator

@shutter wrote:

only standard HSS drill bits.. and a set of taps and dies.... I was thinking of starting witha 6.5 thne 7 then 7.5 but not sure if that last would be too much, and not leave enough metal for the thread to be strong.

In my book the drill for a 8x1.25 pitch is 6.9 and Baldrick1 chart is slight smaller at 6.8

A easy way to remember is to take the pitch from the size 8-1.25 = 6.75

Therefore if you use your 6.5 drill that's approx 11.8 thousands of an inch or 5.9 each side smaller and brass being quite soft it's negligible not like taping stainless steel

Like I said before try in a spare piece of brass use plenty of lubricant and back off every quarter of a turn and remove the swarf so the tap does not jam

Good luck

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Printer Friendly Page

- Plusnet Community

- :

- Forum

- :

- Other forums

- :

- Tech Help - Software/Hardware etc

- :

- Re: Drilling and tapping in solid brass.